Building a Robust System with Industrial PCs: Tips and Tricks

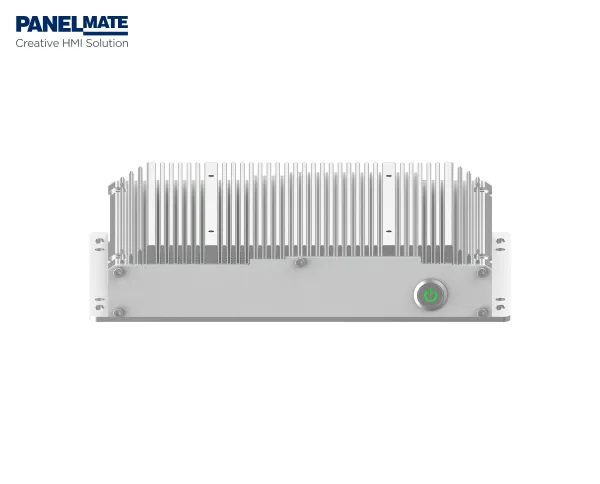

In today's fast-paced industrial landscape, the reliability of systems is paramount. Industrial PCs play a crucial role in ensuring operational efficiency and handling mission-critical functions. These specialized computers are designed to operate in harsh environments, providing robust solutions for industries such as manufacturing, oil & gas, automotive, and more. However, selecting and maintaining the right Industrial PC is crucial to overcoming the unique challenges these environments present.

Choosing the Right Industrial PC for Your Application

When selecting an Industrial PC, it's essential to consider specific factors to ensure it meets the demands of your application. Key considerations include:

- Operating Temperature Range: Industrial environments often experience wide temperature fluctuations. Look for PCs that can operate in extreme temperatures to ensure continuous performance.

- Shock and Vibration Resistance: Some environments are prone to mechanical shocks and vibrations. Industrial PCs with robust shock and vibration protection can withstand these conditions without malfunctioning.

- Protection Class Ratings: These ratings indicate the protection level against environmental factors like dust, moisture, and liquids. A higher Protection Class rating (e.g., IP65 or IP67) means better environmental protection.

Understanding these specifications helps in choosing a PC that can handle the rigors of your environment. For example, a manufacturing plant in a coastal area would require a PC with high protection against moisture, while a factory exposed to regular dust might need a PC with a higher dust protection rating.

Maximizing Reliability and Performance with Strategic Configuration

Configuring an Industrial PC for optimal reliability and performance involves several strategic steps. Here are some key configurations to consider:

- Redundant Power Supplies: Implementing redundant power supplies ensures uninterrupted operation and prevents downtime. This is particularly crucial in mission-critical applications where even brief interruptions can result in significant downtime.

- Cooling Systems: Cooling is essential, especially in high-temperature environments. Proper cooling ensures performance and longevity by maintaining optimal operating temperatures. Enclosure fans, heat sinks, and liquid cooling solutions can be integrated based on the specific needs of your application.

- Connectivity Options: Choose connectivity options based on the application's needs. Local networks might require gigabit Ethernet, while distributed systems might need redundant Ethernet redundancy protocols like EtherCAT or Profinet. Ensure that your network infrastructure can support the chosen solutions.

Regular maintenance and updates are also essential to keep the system running smoothly. Regular checks, firmware updates, and software patches help ensure the system remains robust and secure. Here are some best practices:

- Proactive Maintenance Schedule: Develop a maintenance schedule to catch potential issues early. Schedule regular checks and updates to prevent system failures.

- Stay Updated with Industry Standards and Best Practices: Keeping up with the latest industry standards and best practices keeps your system performing optimally. Regularly review and adopt new technologies and methodologies.

Case Study: Overcoming Challenges with a Robust Industrial PC System

A real-world example can illustrate how an Industrial PC system can make a significant impact. Consider a manufacturing plant that was facing equipment downtime and inefficiencies. By implementing an Industrial PC solution, the plant was able to address these issues effectively:

- Reduction in Downtime: The system reduced downtime by 30%, translating to significant cost savings and increased productivity.

- Increased Throughput: Throughput increased by 25%, leading to better utilization of resources and higher production output.

This case study highlights how tailored Industrial PC systems can solve real-world problems, improving operational efficiency and productivity in manufacturing and other industrial settings. By closely examining the specific needs and challenges of the plant, the solution provided substantial benefits.

Enhancing System Security with Industrial PCs

Cybersecurity is a critical concern in industrial applications. Industrial PCs are equipped with features such as:

- Secure Boot: Ensures that the system boots only from trusted operating systems and firmware. This prevents unauthorized access and the execution of malware.

- Intrusion Detection: Monitors for unauthorized access and alerts when suspicious activity is detected. This helps in promptly addressing potential security breaches.

These measures ensure that the system remains robust against unauthorized access, safeguarding sensitive data and operations. Additionally, secure connectivity options, such as secure remote access protocols, prevent unauthorized access to the network, further enhancing system security.

Tips for Long-Term Support and Maintenance

Maintaining a robust system requires proactive support and maintenance. Here are some tips:

- Choose Vendors with Strong Support Networks: This ensures timely assistance when needed. Look for vendors with dedicated support teams and a history of reliable service.

- Proactive Maintenance Schedule: Regular checks and updates catch potential issues early, minimizing downtime. Schedule maintenance based on manufacturer recommendations and observed usage patterns.

- Stay Updated with Industry Standards and Best Practices: Keeping up with the latest industry standards and best practices keeps your system performing optimally. Regularly review and adopt new technologies and methodologies.

- Regular Checks and Training: Conduct regular checks and provide necessary training to maintain long-term system reliability and efficiency. Training your staff ensures they can handle routine maintenance and troubleshoot common issues.

Conclusion

Selecting the right Industrial PC and implementing best practices are essential for building a robust system. Each step, from choosing the appropriate specifications to configuring the system effectively, plays a crucial role in ensuring reliability and performance. By addressing the unique challenges of industrial environments and prioritizing cybersecurity and maintenance, you can create a system that stands the test of time.

Embrace these tips to build a robust system with Industrial PCs, ensuring operational excellence in any environment. Utilize industry insights and real-world examples to enhance your knowledge and make informed decisions. Together, we can achieve unparalleled reliability and performance in our industrial systems.